Apple's Next Big Leap: iOS 26 Set to Revolutionize Your iPhone on September 15th

Get Ready for Liquid Glass: The Revolutionary Material Transforming Our World

Imagine a coating so thin it's virtually invisible, yet powerful enough to protect almost any surface from damage, bacteria, and environmental wear. Welcome to the extraordinary world of liquid glass – a groundbreaking technology that's set to revolutionize how we think about protection and durability.

Liquid glass, scientifically known as silicon dioxide (SiO2), is a remarkable nano-material that creates an ultra-thin, transparent protective layer when applied to surfaces. At just 100 nanometers thick – that's 500 times thinner than a human hair – this innovative coating delivers extraordinary protection without changing the appearance or texture of the original material.

Incredible Applications

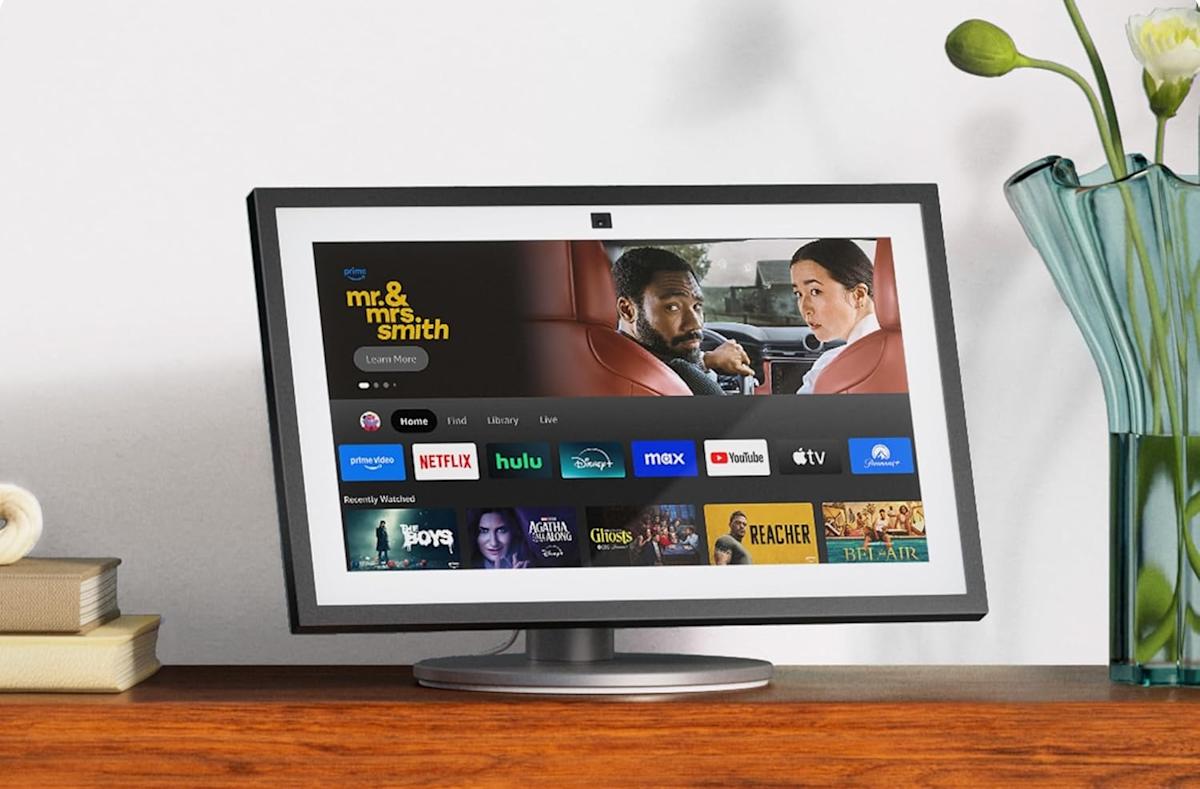

The potential applications for liquid glass are mind-blowing. From healthcare facilities seeking advanced antimicrobial surfaces to industrial settings requiring robust equipment protection, this technology is proving to be a game-changer. Hospitals can create self-sterilizing surfaces, smartphones can become scratch-resistant, and fabrics can become stain-proof and water-repellent.

How It Works

When applied, liquid glass forms an invisible, breathable layer that bonds at a molecular level. This unique characteristic allows surfaces to maintain their original properties while gaining remarkable protective qualities. It's like giving every surface a microscopic suit of armor that's completely transparent.

Environmental and Economic Benefits

Beyond its protective capabilities, liquid glass offers significant environmental advantages. By extending the lifespan of materials and reducing the need for frequent replacements, it contributes to sustainability efforts. The coating is non-toxic, environmentally friendly, and can potentially reduce waste across multiple industries.

As research continues and technology advances, liquid glass stands poised to transform how we protect and preserve surfaces. From medical equipment to everyday consumer products, this nano-technology represents an exciting glimpse into a more durable, efficient future.